- OEE measures equipment efficiency via availability, performance, and quality metrics.

- It identifies inefficiencies like downtime, slow cycles, or quality defects.

- OEE helps streamline workflows, reduce waste, and boost operational effectiveness.

- A world-class OEE score is 85%, which indicates optimum manufacturing efficiency.

- OEE supports lean manufacturing and total productive maintenance goals.

- Overall Equipment Effectiveness

- How Is Overall Equipment Effectiveness Calculated?

- Steps to Calculating Overall Equipment Effectiveness

- What Are the Components of the OEE Framework

- What Is a Good OEE Score and How Should It Be Interpreted?

- How Can You Improve Overall Equipment Effectiveness?

- Practical Applications and Benefits of OEE

- How Can You Measure And Monitor OEE Effectively?

- Frequently Asked Questions About Overall Equipment Effectiveness

Overall Equipment Effectiveness

Overall Equipment Effectiveness (OEE) is a crucial metric in manufacturing that measures efficiency by evaluating three key factors: equipment availability, performance, and quality. It provides a standardized metric to assess how well machines are operating compared to their maximum potential capacity.

OEE helps pinpoint specific issues that may be causing inefficiencies, such as unplanned downtime or low output speeds. This allows businesses to implement targeted interventions to increase OEE performance and drive overall asset effectiveness.

Therefore, by measuring OEE and analyzing its components, manufacturers can streamline their workflows, reduce waste, and align with their overall operational goals.

Consequently, OEE plays a vital role in ensuring the success of manufacturing operations. It serves as an invaluable tool for manufacturers who are looking to increase efficiency and profitability.

How Is Overall Equipment Effectiveness Calculated?

OEE = Availability x Performance x Quality

Each factor addresses a specific aspect of equipment effectiveness. Such as, availability measures the actual operating time. Performance, on the other hand, gauges whether equipment is operating at its maximum capacity or not. Moreover, quality reflects the proportion of defect-free products relative to the total output.

Measuring OEE is too crucial for manufacturers because it helps them to identify issues like unexpected downtime, slower-than-optimal production rates, or defects that impact product quality.

By understanding OEE performance, you can implement targeted improvements, such as better maintenance schedules or workflow adjustments. This data-driven approach enhances operational efficiency, reduces waste, and supports long-term productivity gains.

For instance, imagine a machine has 720 minutes of scheduled runtime but was operational for 600 minutes, resulting in:

Availability = 83.3%

During this time, it produced 1,000 units at a rate of 83.3% of its maximum speed (Performance = 83.3%), and 900 of these units were defect-free (Quality = 90%). So, the OEE calculation would be:

0.833 x 0.833 x 0.9 = 62.5%

This means that the machine is only operating at 62.5% of its full potential. It indicates room for improvement in availability, performance, and quality.

Steps to Calculating Overall Equipment Effectiveness

Calculating Overall Equipment Effectiveness (OEE) involves evaluating three key metrics: Availability, Performance, and Quality. These components collectively measure how effectively manufacturing equipment operates during scheduled production time. Let’s discuss each step in detail below.

How Do You Calculate Availability in OEE?

Availability is a measure of how much of the planned production time equipment is actually operational. It highlights periods when machines are down due to issues like breakdowns, maintenance, or setups. This makes it a vital component of Overall Equipment Effectiveness (OEE).

Because without strong availability figures, even well-performing equipment with high-quality output won’t reach its full potential, as operational time is limited.

The formula for availability is simple yet effective:

Availability = Actual Operating TIme / Planned Production Time x 100

For instance, if a machine is scheduled to run for 480 minutes but operates for only 400 minutes due to unplanned maintenance, its availability would be (400 ÷ 480) × 100 = 83.3%. This figure reflects how effectively the equipment is utilized during its intended operating time.

However, in order to truly maximize equipment availability, manufacturers must also consider the impact of planned downtime on production. You can mitigate these losses by implementing predictive maintenance strategies. These strategies identify potential issues before they cause failures.

Additionally, streamlining setup and changeover processes can also significantly reduce downtime, ensuring that equipment stays operational and aligned with OEE efficiency goals. This will ultimately lead to improved overall equipment effectiveness and increased profitability.

The above-mentioned image has been sourced from LinkedIn.

How Do You Calculate Performance In OEE?

Performance is a crucial component of Overall Equipment Effectiveness (OEE) as it directly impacts output rates and overall manufacturing efficiency. Performance efficiency evaluates how effectively equipment operates compared to its maximum potential capacity. This metric identifies speed losses, such as slow cycles or brief stops, that hinder optimal productivity.

The formula for calculating performance is simple:

Performance = Ideal Cycle Time x Total Units Produce / Actual Operating Time x 100

Performance can be measured in a few simple steps:

- Identify the Ideal Cycle Time: The ideal cycle time is the theoretical minimum time it takes to produce one unit of a product.

- Calculate the Theoretical Production Time: Once you have determined the ideal cycle time, you can multiply it by the total units produced during a specific period to obtain the theoretical production time.

- Compare Against Actual Operating Time: Divide the theoretical production time by the actual operating time to calculate performance efficiency. This will give you a percentage that represents how close your equipment is operating to its maximum potential capacity.

Apart from these steps, there are certain common factors that can affect performance rates and need to be addressed for optimal results. Such as slow cycles, small stops, and variability in operator expertise. So, addressing these factors is essential for improving performance and enhancing OEE.

How Do You Calculate Quality in OEE?

Quality in Overall Equipment Effectiveness (OEE) focuses on the proportion of defect-free products in total production. It evaluates how well a manufacturing process delivers products that meet quality standards. It also highlights areas where waste can be minimized.

This component is also crucial for maximizing efficiency since defective goods consume resources heavily without contributing to usable output. For example, defective items may require additional processing, which prolongs production times and decreases effective equipment utilization. It directly lowers productivity and profitability.

The formula for calculating quality is straightforward:

Quality = Number of Defect Free Units / Total Number of Units Produced x 100

You can measure it in some simple steps:

- First, determine the total production output during a specific period.

- Next, record the number of units that meet quality standards.

- Then, divide the number of defect-free units by the total number produced and multiply by 100 to calculate the quality percentage.

- Finally, compare the result with industry standards or past performance to identify areas for improvement.

What Are the Components of the OEE Framework

The Overall Equipment Effectiveness (OEE) framework consists of three key components: Availability, Performance, and Quality. These components are multiplied to calculate the OEE score and provide insights into equipment utilization and productivity. Such as:

- Availability: This component measures the percentage of scheduled production time that equipment is operational. It takes into account any downtime due to breakdowns, maintenance, or setup changes.

- Performance: The performance component evaluates whether equipment operates at its maximum speed by comparing actual output to the ideal cycle time. It also highlights losses from slow cycles or minor stops.

- Quality: This component assesses the proportion of defect-free products produced, identifying waste caused by defects and rework.

Each component plays a critical role in improving equipment efficiency and minimizing waste. For example, increasing availability reduces downtime, optimizing performance enhances production speed, and improving quality minimizes defective outputs.

So, together, these metrics enable manufacturers to target inefficiencies systematically and enhance overall equipment effectiveness.

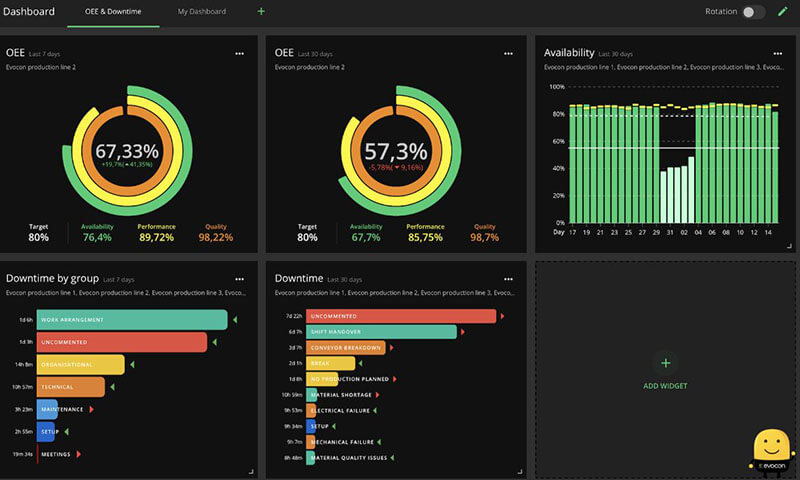

This image has been taken from Evocon. It showcases an interactive representation of OEE

The above is an interactive representation of OEE that often uses charts or dashboards to display real-time data for each component. This helps teams to monitor progress and identify areas for improvement. By focusing on this real-time data, manufacturers can achieve higher OEE performance and align with operational equipment efficiency goals.

The Timly Software in Use

Optimized Device Management With Innovative Self-Inventory

SodaStream is the world market leader for water sparkling systems for domestic use and has a lot of IT equipment at its various locations. Many colleagues now work from their home offices. A digital solution for the efficient management of IT end devices became necessary...

Panasonic x Timly: Driving Technological Innovation

One of the most remarkable aspects of human ingenuity is our ability to innovate. Innovation is embedded in the DNA of consumer electronics giant Panasonic, which has diversified into a number of sectors, from heavy industry to construction...

Manage Video Equipment Efficiently Without Much Effort

The Hamburg media company always does outstanding journalistic work and is characterized by independent reporting. In order to maintain journalistic quality, the teams work with highly specialized devices – these need to be managed efficiently...

Smart City Asset Management – Timly in Use at DIGOOH

The core business of DIGOOH Media GmbH in Cologne is to manage digital city light posters (DCLP) for outdoor use in various cities in Germany. The challenge here lies in making the client’s communication message always available at the right time, in the right place...

(No credit card required)

What Is a Good OEE Score and How Should It Be Interpreted?

Because, achieving 85% OEE represents a well-optimized process where equipment operates with minimal downtime, produces at efficient speeds, and outputs high-quality goods.

However, reaching this level typically involves strong process controls, predictive maintenance, and robust quality management practices.

Below are some other standard benchmarks that are used to evaluate OEE performance:

- 85% or higher: World-class performance. It shows highly efficient and optimized operations.

- 60%–85%: Good performance. This can be achievable with some improvement efforts in availability, performance, or quality.

- 40%–60%: Average performance. It indicates significant room for improvement to minimize losses.

- Below 40%: Poor performance. It requires a focused strategy to address inefficiencies and increase productivity.

However, it’s important to note that OEE scores differ across industries due to the unique demands of production processes. Such industries, like continuous manufacturing and food processing, often achieve higher OEE scores, with 90% due to streamlined workflows and consistent output.

On the other hand, discrete manufacturing, such as automotive assembly lines, may consider 75% OEE acceptable, as frequent changeovers and product customization naturally introduce more variability here.

So, understanding these variations helps manufacturers set realistic targets according to their industry’s challenges.

How Can You Improve Overall Equipment Effectiveness?

You can improve Overall Equipment Effectiveness (OEE) by identifying inefficiencies in availability, performance, and quality. Then, you can implement targeted strategies to address these areas.

Below, we have outlined six effective strategies for improving OEE, potential challenges, and the tools that can drive success.

- Perform preventive and predictive maintenance by scheduling routine checks and using data to predict and prevent failures.

- Optimize production planning to streamline workflows and minimize changeover times with techniques like SMED.

- Provide operator training to enhance skills, reduce errors, and improve machine utilization.

- Utilize real-time monitoring with tools like Timly for live tracking, spotting, and resolving inefficiencies instantly.

- Implement process optimization to eliminate waste and bottlenecks, improving overall flow.

- Focus on quality control through regular audits and quality measures, ensuring defect-free production and reduced waste.

Manufacturers often encounter recurring obstacles, such as equipment downtime, lengthy changeovers, and inconsistent quality standards. These challenges occur due to unplanned equipment breakdowns, extended setup times during product changes, and defective products. However, tackling these challenges requires a structured approach and proactive measures.

Because, availability is the foundation of OEE, and any loss in this area can have a ripple effect on performance and quality metrics. The “Six Big Losses” in manufacturing are the leading causes of inefficiencies in availability, performance, and quality. Thus addressing these losses is essential to improving OEE and eliminating waste. The six categories include:

- Breakdowns caused by unexpected equipment failures, reducing availability.

- Setup and Adjustments, such as changeovers, interrupt operations and reduce uptime.

- Small Stops from minor production disruptions or adjustments that waste time.

- Reduced Speed when machines operate below their optimal rates, impacting performance.

- Defects that lead to product rework or waste directly harm quality.

- Start-up losses occur during initial production or ramp-up stages and affect all three OEE components.

Understanding these losses makes it easier to implement targeted strategies. Timly’s software can also support this process by providing detailed insights into each loss category. With Timly’s software solutions, manufacturers can achieve higher OEE, ensuring improved operational equipment efficiency and sustainable growth.

Practical Applications and Benefits of OEE

Tracking Overall Equipment Effectiveness (OEE) delivers significant value for manufacturers. It offers actionable insights to improve productivity, reduce waste, and maximize equipment usage. This overall helps to eliminate production bottlenecks, reduce unplanned downtime, and improve product quality by minimizing defects and waste.

That’s the reason that by increasing equipment utilization, OEE ensures higher output without additional resources. Furthermore, it supports scalability by aligning operational processes with the demands of growing production.

OEE also complements Lean Manufacturing and Total Productive Maintenance (TPM) objectives. By eliminating waste and improving reliability, it aligns operational goals with continuous improvement principles. For example, maintaining consistent OEE performance ensures cost-effective workflows and streamlined production processes.

By revealing hidden inefficiencies like unplanned downtime or slow cycles, OEE further empowers manufacturers to address root causes proactively. This insight equips manufacturers to address the root causes of inefficiencies and helps in achieving sustainable growth and higher productivity.

To achieve this, you can also use Timly’s tools for better asset tracking and maintenance management. Timly’s real-time data analysis helps manufacturers to find hidden inefficiencies. This proactive approach enables businesses to make better decisions that enhance workflows and drive profitability.

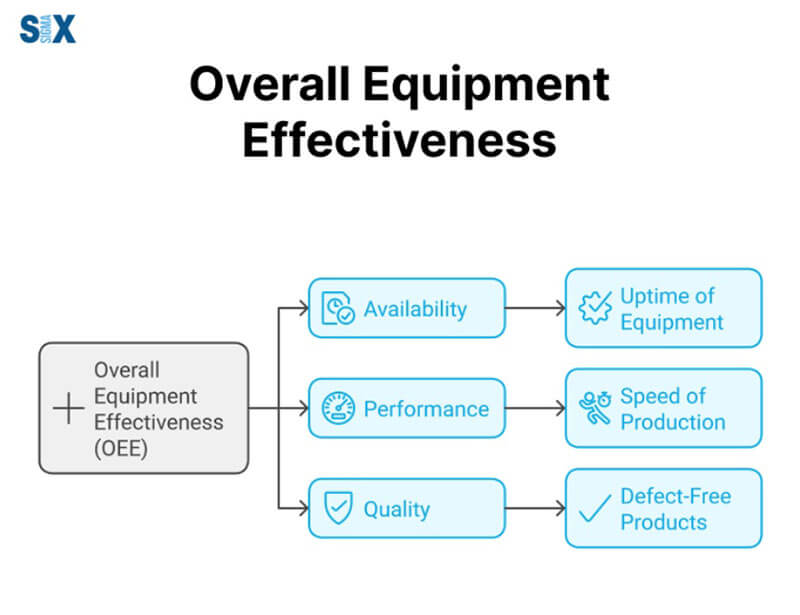

How Can You Measure And Monitor OEE Effectively?

The image is sourced from 6 Sigma

Effectively measuring and monitoring OEE requires standardized practices and tools for accurate calculations and ongoing improvement. You can achieve this by focusing on three critical factors: availability, performance, and quality. By monitoring these aspects at key points in your production process, you can gain valuable insights into where inefficiencies are occurring.

But how often should you measure OEE?

Well, you can measure daily for essential equipment. Weekly to identify broader trends and monthly for long-term strategic insights.

However, businesses should avoid a few common mistakes, such as outdated benchmarks, ignoring minor inefficiencies, or overlooking defects, while monitoring OEE. As this can help them maintain accurate and meaningful evaluations.

Real-time monitoring is also crucial for achieving sustainable improvements. Timly equips manufacturers with tools designed for real-time OEE tracking, predictive maintenance, and data analysis.

This enables businesses to monitor ongoing performance, identify bottlenecks, and implement corrective actions immediately. To see how it works, book a no-obligation online meeting with us today or start with your free trial account directly.

Frequently Asked Questions About Overall Equipment Effectiveness

What Is Overall Equipment Effectiveness?

OEE is a comprehensive metric used in manufacturing to measure efficiency. It evaluates three components, availability, performance, and quality, to determine how effectively equipment is utilized relative to its full potential.

What Are Common Challenges in Achieving High OEE?

The common challenges in achieving higher OEE include unplanned downtimes, variations in operator practices, and inconsistencies in product quality. However, businesses can overcome these challenges by investing in advanced tracking tools, better training, and robust maintenance routines.

Recommended for you:

Book an online demo - free and without obligation - or create your free trial account directly.