Key Takeaways:

- Effective warehouse organization ensures faster inventory management, reduces accidents, and creates a more efficient work environment.

- The 5S principles (Sort, Set in Order, Shine, Standardize, Sustain) offer a methodology for organizing and maintaining a productive warehouse environment.

- Optimal warehouse layout includes receiving, storage, packing, and shipping zones, designed to minimize travel time and congestion while maximizing space utilization.

In This Article:

- How to Manage a Warehouse Organization?

- What Are the Best Warehouse Organization Methods?

- What Is the Most Efficient Set up for a Warehouse Layout?

- Best Way to Design a Warehouse Floor Plan

- How to Organize Warehouse Shelving?

- Organizing a Warehouse With Slotting, Labeling and Software Support

- How to Improve Storage Management With an Organized Warehouse

- What Is the Best Way to Organize a Warehouse for Maintenance and Efficiency?

- Frequently Asked Questions About ‘Warehouse Organization'

How to Manage a Warehouse Organization?

A good warehouse organization is important to ensure that inventory management, shipping, and delivery of items run smoothly. By having a well-managed warehouse, you can ensure that there is faster and more accurate inventory management, a reduced risk of accidents and injuries, a more efficient work environment, the removal of waste and minimized product damage, and the reduction of labor costs, thus streamlining processes and saving costs.

In order to determine the current state of your warehouse organization, you will need to:

- Have a walkthrough of the warehouse and identify areas that are disorganized or pose a hazard. Determine if there are any inventory issues, such as stockouts, overstocking, or discrepancies.

- Look at the processes and evaluate if there is room for better streamlining. Feedback from employees on the state of the warehouse is important to help with improvement.

- Create a safety audit to help determine if there are any hazards and create a plan to mitigate them.

What Are the 5s Principles of a Warehouse Organization System?

The 5s principles of a warehouse organization system are a methodology that helps organize and maintain a productive and efficient work environment. These principles are sort, set in order, shine, standardize, and sustain.

- Sort works on removing all unwanted items from the workspace in order to have a clutter-free zone.

- Set in order focuses on organizing assets in a proper manner for optimal efficiency.

- Shine focuses on clearing and maintaining dust and debris to create a clean and safe environment.

- Standardize helps establish standards for organizing workspaces, create procedures, and provide training to employees regarding maintenance and procedures.

- Sustain focuses on continuously monitoring and maintaining workspaces over time.

What Are the Best Warehouse Organization Methods?

The best warehouse organization methods are those that maintain a work environment that is efficient, safe, and productive. Let us look at some of the important methods, which are pallet racking systems, wire containers, ergonomic equipment, and recycling practices.

A pallet racking system is an important form of storage as it is versatile and efficient. By using this system, you can maximize storage and minimize floor space. This is because palletized materials are kept at a horizontal level and stocked on various levels. This racking system allows you to store large amounts of items in a small space, provides easy access, and is cost-effective.

Wire containers are a versatile storage solution used in a multitude of applications. Their wire mesh design can accommodate a wide range of items, making them ideal for tackling the complexities of how to setup warehouse inventory, including efficient organization and streamlined stock tracking. The benefits of using such a flexible storage solution include their adaptability for various settings, ease of maintenance, and cost-effectiveness.

Ergonomic equipment helps to improve productivity, safety and the warehouse because it reduces the risk of injury. The benefits of having ergonomic equipment are that it helps to reduce physical strain, reduces the time and effort that are needed for a task, and reduces the risk of injury.

Recycling practices are another method for maintaining an organized warehouse, as they help reduce waste, disposal costs, and the environmental impact on the warehouse, which helps increase sustainability.

Over 500 Companies, Schools and Cities Rely on Timly

(No credit card required)

What Is the Most Efficient Set up for a Warehouse Layout?

An efficient warehouse layout is crucial for optimizing operations. By strategically mapping out the warehouse space, you can reduce costs and increase efficiency. A well-designed layout ensures optimal flow and organization, leading to smoother operations. Here’s how an efficient setup would look like:

- It will have a receiving zone that helps facilitate unloading and incoming items. This area should have space for pallets, forklifts, and personnel.

- Should have a receiving zone that is designed to store inventory. It has a shelving and racking system, which reduces travel time.

- Has a packing zone that is dedicated to the efficient packing and shipping of items.

- A shipping zone that focuses on the loading and shipping of goods.

To map out the warehouse for optimal layout, consider these guidelines:

- Warehouse space should be measured to determine the square footage.

- Determine the workflow of the warehouse that focuses on storage, packing, and shipping.

- Design the layout and define the key areas.

- Optimize the layout by focusing on minimal travel time and congestion.

Best Way to Design a Warehouse Floor Plan

The best way to design a warehouse floor plan is to ensure that it provides a proper workflow and maximizes space. Here is a step-by-step process for devising an effective warehouse floor plan.

Step 1: Determine and calculate the total square foot of the warehouse. Once done, identify the type of products, storage space, and number of employees and equipment that are there. This will help you create a workflow and production process.

Step 2: Use flow planning software or even graph paper to come up with schematics. Measure the warehouse space, locate where the doors and windows are going to be located and locate electrical and lighting outlets.

Step 3: Locate the areas throughout the warehouse that are intended for receiving, storage, picking, packing, and shipping. Decide on the workflow processes and the layouts for each piece of equipment and storage area.

Step 4: Measure the storage layout and find out which methods are the best, such as vertical storage, shelving, and racking systems. Use inventory management and tracking systems to plan out this process and learn how to improve inventory management.

Step 5: Ensure that the layout is safe and that employees and equipment are able to access it. Make sure that there are safety features such as emergency exits, fire extinguishers, and first aid kits. Ensure that there is proper ventilation, lighting, and space for disabled employees.

Step 6: Simulate the workflow and processes so that bottlenecks and inefficiencies can be sorted out. Use 3D software or a simulation to test out the design, refine, and workflow issues.

Step 7: Monitor the layout as required and evaluate and improve the workflow whenever necessary.

Create Accessible Aisles

It is important to create accessible aisles to ensure productivity and safety. This is because the aisles need to be wide to accommodate equipment, personnel, and goods. It will showcase a smooth, flowing movement throughout the warehouse.

To design an aisle, you will need a width that is at least 3 feet wider than the equipment. There needs to be clear colored markings, such as lines, dots, or stripes, to define the aisle space. By having a clear and obstacle-free aisle, you will ensure that employees are productive as they reduce the time spent going through congested areas. To add on, it also provides safety, reduces clutter, reduces the risk of accidents and injuries and allows for easy streamlining of workflows and easy navigation.

Use Vertical Space

In order to maximize vertical spaces and increase storage capacity, it is best to use a shelving unit or mezzanine. Let us look at some tips on how to effectively use them.

- Select a shelving unit that is sturdy and able to withstand heavy weights.

- Measure the space where the shelving unit will be placed.

- Use adjustable shelves so that you can customize the storage space.

- Place shelves that have a comfortable height and use step stools to access high shelves.

The importance of safe practices lies in the need to prevent any accidents and injuries when accessing items stored at height.

- Use a ladder that is sturdy and secure.

- Always have three points of contact when using a ladder: use either 2 hands and 1 foot or 2 feet and one hand.

- Always face the ladder when climbing up and down.

- Use a spotter or ask someone to help you access items that are in a high place.

- Regularly check to see if there is any damage or wear and tear on the shelving unit.

Improve Picking Paths

Let us look at strategies that will help improve picking paths. This is important because it impacts efficiency and productivity when it comes to fulfilling orders. Here are some useful strategies:

- Use an exhaustive search algorithm to find the shortest route.

- The nearest neighbor algorithm focuses on the point that is close to your starting point and this removes the need to think about the process.

- Floyd’s algorithm helps search for the optimal distance between all the known points. This provides quick movement for a traveling salesperson’s problem.

Here are some tips for using software tools to map and optimize picking paths:

- Use software tools to help visualize warehouse travel and identify areas of congestion.

- Try different batching strategies for travel time to ensure optimization.

- Optimize work allocation to increase productivity.

- Analyze the impact on marketing plans and travel time and adjust where needed.

- Use software to optimize picking paths, helping reduce travel time and increase efficiency.

- Design heat maps to determine congested areas and pick-up routes.

- Use picking path optimization software to help reduce travel time and streamline order fulfillment.

The Timly asset tracking software in use at SodaStream

Everything Under Control With One Solution – The Intuitive Asset Tracking Software

(No credit card required)

How to Organize Warehouse Shelving?

To organize warehouse shelving, it is important to ensure that inventory is categorized. Here are some ways to categorize items:

- ABC analysis. The inventory is divided into three categories: A for high demand or value, B for medium demand or value, and C for low demand and value. This provides prioritization and retrieval methods.

- First in, First Out (FIFO). This is used to work on the first items that were received and will be sent out in order to make way for newer items.

Labeling and signage play a huge role in maintaining shelf organization. You will need to ensure that a unique identifier is assigned to each item, the labels are readable with the right description, quantity, and storage location, and there is appropriate signage for employees and visitors.

Organizing a Warehouse With Slotting, Labeling and Software Support

Slotting is a strategy that helps organize warehouse storage to maximize efficiency by analyzing the location of inventory. This helps reduce handling costs, improve order fulfillment, and increase productivity. To create an effective slotting strategy, you will need to ensure the characteristics of the product, its SKU velocity, the warehouse routes which employees take, and inventory levels.

By implementing slotting strategies, warehouses can reduce handling costs, improve order fulfillment, reduce storage, and enhance inventory visibility. A robust labeling system is important for an efficient warehouse. Using accurate and consistent labeling helps to identify products, streamline tracking, reduce errors, improve visibility, and enhance product safety and compliance.

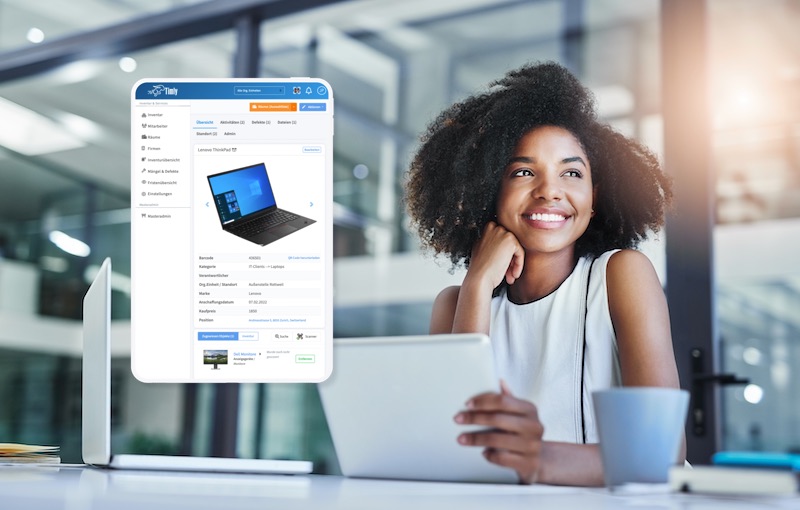

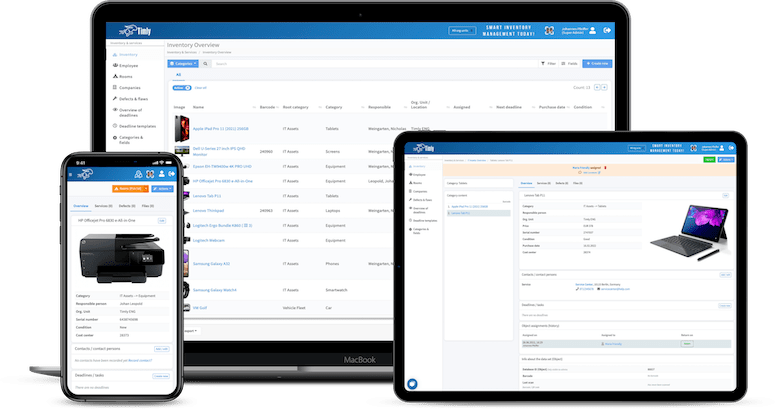

Using warehouse management software like Timly can help streamline inventory and operations management. It helps to provide inventory tracking and management, integration with other systems and platforms, and data analytics to help provide insights. Overall, it helps to streamline inventory and operations management.

How to Improve Storage Management With an Organized Warehouse

In order to improve storage management with an organized warehouse, it is important that space utilization is determined. That is, you will need to measure the current space utilization and identify room for improvement. Let us look at some methods:

Calculate the total square footage of the warehouse, measure the volume of each item in the warehouse, calculate the size of each storage slot, calculate the size of each slot, and then determine the percentage of space that can be used in the warehouse by dividing the total storage space with the total warehouse space.

What Is the Best Way to Organize a Warehouse for Maintenance and Efficiency?

The best way to organize a warehouse is by considering how the new system will enable efficient operations and streamlined maintenance. It is important to ensure that space is organized so that operations run smoothly, and that the potential for errors and waste is minimized. Let us look at some best practices:

- It is important that the warehouse is kept clean for a safe and secure work environment. This also prevents damage to equipment and production and improves overall efficiency.

- Regular inspections help identify potential issues before they become a major concern concurrently, ensuring compliance and safety.

- In order to enable an efficient receiving process, it is important to ensure that the specific area for receiving and unloading items is not congested.

- Ensure that there is a clear and organized system to track and store items.

- Use barcode scanners or RFID tags to streamline receiving while reducing errors.

- Provide training to staff so that they can inspect items and report if there are any damages.

Get Started Now – With Digital Asset Tracking Software!

(No credit card required)

Frequently Asked Questions About ‘Warehouse Organization’

How to Manage a Warehouse Organization?

What Are the Best Warehouse Organization Methods?

The Inventory Software for Your Success

A wide range of intelligent functions allows you to easily manage your entire company’s inventory. Try Timly asset tracking software now for free and see how easy it is to save time and resources.

Manage All Assets

Whether IT resources, tools, machines, vehicle fleet, furniture or contracts: everything in Timly.

Mobile Available Everywhere

Localise your assets with the integrated barcode scanner for smartphones & tablets.

Clever Assignment

Easily assign assets to people, projects, rooms, locations or external service providers.

Digital File Management

Digitally store important information, files, documents, audit trails & contacts for your assets.

GPS Recording

Save the exact GPS location of your assets with one scan. All GPS data historically verifiable.

Maintenance Management

Recommended for You: