Testing and Marking of Portable Equipment

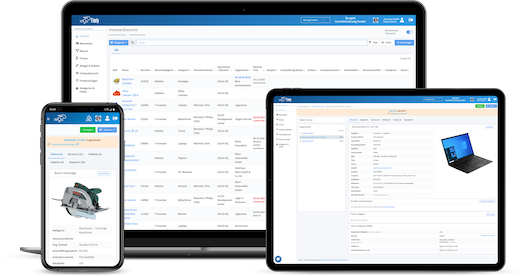

Testing and marking of portable equipment can be efficiently managed by software

The Security-Relevant Subject Area in Every Company

They are used in every business and are considered indispensable tools – we are talking about portable electrical equipment. However, due to their versatile areas of application, they also have decisive disadvantages. The more electrical equipment is available, the faster errors occur when using the devices. Often, the expertise of the employees varies. Furthermore, it is easy to lose track of the equipment if it is not returned to its original place or location after use.

Maintenance software, such as that offered by Timly, can help here. With the help of the software, you have an overview of which employees are authorised to use the equipment. In addition, you reduce downtimes of electrical equipment and unnecessarily incurred repair costs. In addition, the software has a tool management function. Here you can record which colleague was the last to use the electrical equipment and thus organise the work processes more efficiently.

In addition, the Ordinance on Industrial Safety and Health stipulates that the employer may only provide equipment that is “suitable for the conditions prevailing at the workplace and whose intended use ensures safety and health protection”. In order to prevent them from being used in the wrong work areas, it is recommended to make a clearly visible marking with the help of electrical test badges “Application categories K1 and K2”.

What Is Portable Electrical Equipment?

This refers to electrical devices that can be moved easily during operation while still being connected to the supply circuit. Accordingly, they have a plug, weigh less than 23 kg and are not permanently installed in one place. For example:

Office supplies: monitor, computer, printer, floor or table lamp, multiple socket, extension cable, document shredder, scanner, chargers

Electrical machines and tools: jigsaw, cable drum, soldering iron, hand drill, hand lamp, hand circular saw

Household appliances: coffee maker, kettle, hoover

Laboratory equipment: microscope, centrifuge, rotary evaporator, ultrasound bath and much more

Asset Management Software in Use by Our Customers

The Timly software is continuously evolving to meet the needs of our customers. In various success stories, we show you how Timly optimizes processes in companies, thereby saving significant effort. With Timly, inventory management becomes child’s play.

Optimized Device Management With Innovative Self-Inventory

SodaStream is the world market leader for water sparkling systems for domestic use and has a lot of IT equipment at its various locations. Many colleagues now work from their home offices. A digital solution for the efficient management of IT end devices became necessary...

Panasonic x Timly: Driving Technological Innovation

One of the most remarkable aspects of human ingenuity is our ability to innovate. Innovation is embedded in the DNA of consumer electronics giant Panasonic, which has diversified into a number of sectors, from heavy industry to construction...

Manage Video Equipment Efficiently Without Much Effort

The Hamburg media company always does outstanding journalistic work and is characterized by independent reporting. In order to maintain journalistic quality, the teams work with highly specialized devices – these need to be managed efficiently...

Smart City Asset Management – Timly in Use at DIGOOH

The core business of DIGOOH Media GmbH in Cologne is to manage digital city light posters (DCLP) for outdoor use in various cities in Germany. The challenge here lies in making the client’s communication message always available at the right time, in the right place...

(No credit card required)

What Do the Categories K1 and K2 Mean?

The classification of portable electrical equipment is intended to make it easier for every employee to choose the right device, even for those without electrical engineering knowledge. Categories K1 and K2 assign electrical equipment to corresponding areas of use and environmental conditions. In this way, potential hazards due to incorrectly used equipment are minimised.

In order to understand the markings, users should be instructed accordingly. If there is equipment of only one category, the labelling can be omitted. Otherwise, K1 labels or K2 labels are suitable.

For “normal” operation

Examples of areas of application:

Industry, trade, agriculture, hotels, kitchens, laundries, laboratories, locksmiths, toolmaking, machine factories, automotive construction, interior fittings, automotive workshops, manufacturing plants, plastics processing, commercial housekeeping, assembly line series production, laboratories…

Usage characteristics:

Indoor use or outdoor use only with restrictions

Ambient condition:

- Humidity: dry to damp

- Dust exposure: normal

- Mechanical stress: normal

- Effects of oils, acids, alkalis: low

- Effects of corrosion: none

For “rough” operation

Examples of areas of application:

Rooms and facilities in agriculture, steel construction, construction and assembly sites, open-cast mining, foundries, large-scale assembly, outdoor work, boiler and apparatus construction, heavy industry, open-cast mining, chemical industry, work under increased electrical hazard…

Usage characteristics:

Indoor and outdoor use

Ambient condition:

- Humidity: wet

- Dust exposure: high, also conductive dusts

- Mechanical stress: high

- Exposure to oils, acids, alkalis: medium to high

- Corrosion effects: medium to high

Do Portable Electrical Equipment Have to Be Tested?

Yes, all electrical equipment in the company must be checked for safe and proper condition according to Industrial Safety and Health Regulations. This should be done before initial commissioning, after repair or modification and at regular intervals.

Operating resource management can be considerably simplified by specialised software

Which Inspection Intervals Apply to Portable Electrical Equipment?

The inspection intervals must be recorded in the company’s internal risk assessment. The specifications in DGUV Regulation 3 can be used as a guide. Maintenance planners are ideal aids for adhering to the deadlines.

The following guideline values are given, but the inspection period may be extended if the error rate is less than 2%:

| Area | Reference value | maximum check period |

| Workshops, production sites, construction sites | 3 months | 1 year |

| Office | 6 months | 2 year |

| other institutions | 6 months | 1 year |

Here, too, our digital inventory management offers an optimal solution. With just one tool, you always have an overview of all deadlines, defects, maintenance or even repairs.

How and who may test portable electrical equipment?

The test is carried out by a qualified electrician; under certain conditions, an electrically instructed person may also carry out the work. The prerequisites are that the specialist and the suitable measuring and testing equipment are available on site.

The following test steps are necessary to guarantee safe working with portable equipment:

- Inspect: Visual inspection for externally visible defects or improper use.

- Testing: Functional test

- Measure: carry out prescribed measurements (e.g. protective conductor resistance, insulation resistance, protective conductor current, touch current, substitute leakage current, loop resistance)

- Evaluation of the measurement results

- Documentation by means of a test report

- Labelling by means of test badges

As already mentioned in point five, all results of the test must be documented in the form of a test record, handwritten or digital. The records must be kept at least until the subsequent inspection.

Inspection labels, e.g. K1 stickers, have proven their worth for marking successfully tested portable equipment. However, cable labels can also be used. They show every user when the equipment was last tested or when the next test is due. In addition, the classification according to the area of application is made visible by the test labels.

If all regulations regarding correct use, deadlines and inspections are observed, potential hazards in your business are minimised.

Similar Blog Posts:

Book an online demo - free and without obligation - or create your free trial account directly.