Major Construction Site at Bern Train Station: Arge Manages Assets With Timly

The Timly tool management software in use on the large construction site “Zukunft Bahnhof Bern” 🚧 ⛓ 🛠

The ARGE (Bern Train Station)

Start date

2017

Construction time

12 years

Costs

Industry

Actors involved

KIBAG, Wirz, WALO, Kästli

Assets

~2,500 devices & machines

The Challenge: Large Construction Site With Hundreds of Construction Workers & Lots of Devices

With such large construction sites, it is not uncommon for construction progress to be delayed and costs to be adjusted. In order to avoid this as much as possible, a structured organisation is required. Hundreds of construction workers have to work together in a coordinated manner and all their equipment has to be managed with a system. ARGE chose Timly as a partner for this challenge.

The asset management software should be used to coordinate tools, machines and vehicles. The difficulty: For the large construction project, inventory is rented from four different partners. Here, the ARGE always needs a good overview of which device or which machine has just been rented by which company. After all, it should be properly returned after the end of the agreed rental period. – And not just any hammer drill, but exactly the hammer drill that was also borrowed. You also have to keep an eye on the deadlines. With so many pieces of equipment, this is hardly possible without inventory software. Deadlines are easily missed when the equipment count is large and staff are changing.

The Solution: Smart Digital Management of All Devices and Rental Periods With Timly

Manage Inventory of Different Companies Digitally

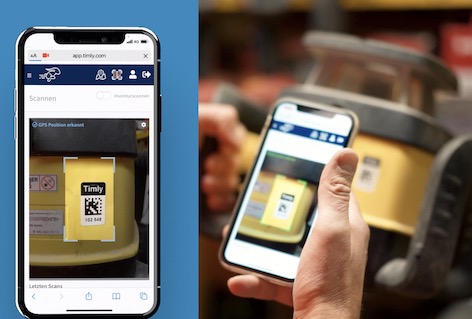

So that the ARGE can always see exactly which tool is on the construction site, how long it will still be available and what costs can be paid or passed on, it uses Timly’s digital tool management system. At the beginning, a large number of the devices and vehicles were recorded and provided with a QR code.

It was not necessary to purchase extra scanners – this is extremely practical, especially for a single construction project – even if it is a very long one – especially because everyone involved has access with their own smartphone.

Gps Tracking for More Predictability

The additional highlight: At the request of the ARGE, all devices and vehicles are also tracked via GPS. Each time an asset is recorded with the QR code scanner on the cell phone, the device is precisely localised and displayed on the map. In this way, the ARGE and the authorised workers know at all times where a specific piece of equipment or the required excavator is located.

The last recorded location can also be determined with the inventory app through the GPS map connection. This is particularly practical, since the major construction site at the Bern train station includes a 1 km long new tunnel. – You don’t want to set off on foot without a plan, but would rather have the desired tool displayed on the map and perhaps have a colleague bring it with you.

Practical User Management

The many workers deployed at the Bern train station come from various large companies (KIBAG, WALO, Kästli and Wirz). Therefore, flexible user management in the inventory software is necessary.

The assignment of different user roles and rights facilitates coordination. Some workers are assigned the simple role of tool users, some as dispatchers. So everyone sees exactly what they need. Specific equipment can be assigned to individual workers or for specific construction stages.

Digital Maintenance Management

Over such a long period of time until the new station is completed, there are always deadlines for maintenance and safety checks to be met. The digital Maintenance Planner, which reminds you when a device needs maintenance, solves this efficiently. In addition, defects or deficiencies can be recorded in a very practical way and documented historically, as can repairs.

Most used functions:

GPS Tracking

Maintenance Management

The Result: Administration & Tool Management Optimised, Costs Saved

Through the documentation in the Timly tool tracking software, we manage to see exactly which company has used which machine and for how long, and can then invoice this. This allows us to work more cost-efficiently.

Using the mobile app, workers can record their devices on site and also lend them to each other in a traceable manner. Based on a minute-by-minute recording of the usage time, the ARGE companies then send each other accurate invoices. – This saves unnecessary effort, avoids errors and provides more flexibility.

Inventory loss is also much less common. The comprehensible history generally ensures that employees treat it with care – because if you are assigned a tool personally, your sense of responsibility increases.

The range of functions offered by the Timly inventory software to the executing consortium at the Bern train station is therefore ideal for the requirements of a large construction site with several companies or subcontractors. This saves time and money and optimises processes.