What Is Maintenance and How Does Software Help?

On this page you will find information on the following topics:

- What Is Maintenance and What Is Repair: A Definition

- Maintenance: Synonymous With Servicing?

- Types and Goals of Maintenance

- Condition-Oriented Maintenance: Tasks and Procedure

- What Is Maintenance Real Estate: Definition and Elements

- What Is Maintenance Buildings: Elements and Strategies

- Example of Definition in Industry

- How to Implement: Industry, Trade, Construction and Other Sectors

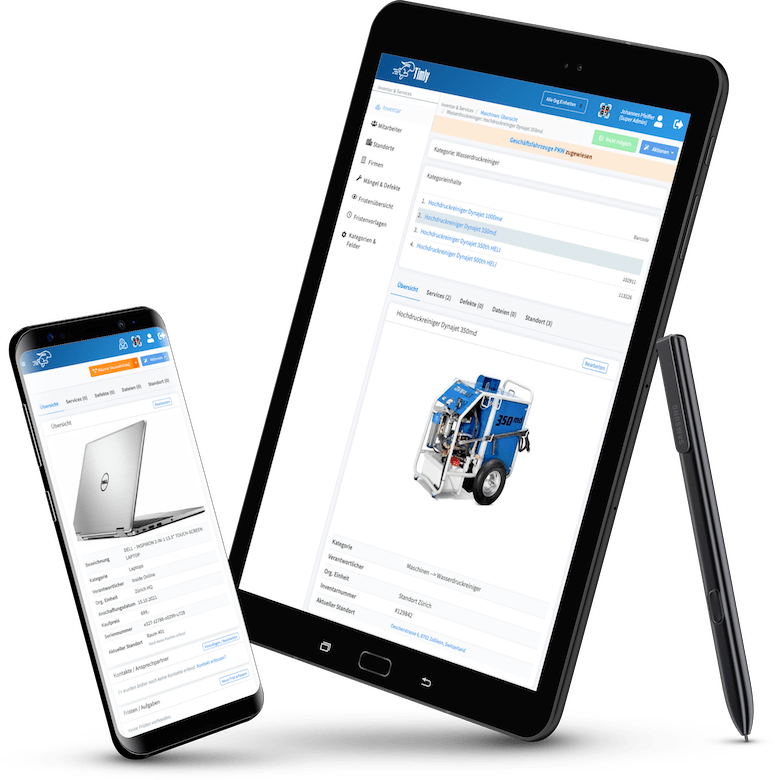

Complicated asset management is a thing of the past – with Timly you always have everything directly at hand

What Is Maintenance and What Is Repair: A Definition

What is maintenance? Although the term is frequently used in areas such as trade, industry, construction or production, it is rarely explained what it actually means. You may therefore be asking yourself: Is there a DIN standard for maintenance? What is the difference to maintenance? And: How can I efficiently document all the inspection dates and defects?

First of all, it is helpful to know that maintenance is a generic term. The corresponding subcategories are maintenance, repair, inspection and improvement. It is therefore the totality of technical and administrative measures to ensure that an object can fulfil its required function in the long term. DIN EN 13306 and DIN 31051 can be consulted for a definition.

Maintenance, on the other hand, is exclusively concerned with restoring the target state in the event of a defect. Nowadays, the use of special software – such as Timly – is recommended for maintenance planning and organisation. It makes sense to interact with the inventory database, as the company inventory is the subject of the maintenance measures.

Maintenance: Synonymous With Servicing?

Many people use the terms maintenance and servicing interchangeably or simultaneously. This can give the impression that they are synonyms. In fact, maintenance is specifically about slowing down the wear and tear of an object. Regular maintenance maintains the operational safety of vehicles, tools or machines. They are thus a part of maintenance planning.

A good digital solution therefore combines inspection dates, documentation and the tracking of defects and deficiencies in one place. While maintenance only means technical measures, servicing also includes certain management measures.

The difference between inspection and maintenance should also not be forgotten: inspection is a review of technical systems or equipment to assess the actual condition with regard to accident prevention. According to DIN 31051, inspection is also a component of maintenance.

Over 600 Companies, Schools and Cities Rely on Timly

Types and Goals of Maintenance

At the management level, clear maintenance documentation enables forward planning of costs for inspections, spare parts or maintenance material. Some maintenance strategies are reactive and preservative, such as preventive maintenance. This model uses fixed time intervals based on general experience of component life and wear.

This, as well as Breakdown Maintenance, is considered uneconomical and unsustainable. After all, equipment can also fail between the regular maintenance measures. On the other hand, rigid maintenance schedules sometimes lead to the replacement of fully functional machine parts.

With the Timly maintenance management software, you always have an overview of all maintenance dates and requirements.

Condition-Oriented Maintenance: Tasks and Procedure

As companies become increasingly digitalised, condition-based maintenance is becoming more and more popular. But what is maintenance that is condition-based? The core of this strategy is the permanent monitoring of the states of system components with the help of sensors. The smallest deviations from normal operation, such as changes in vibration behaviour or sound, are reported via the Internet of Things.

In this way, an impending malfunction can be identified and counteracted. A stable and secure internet as a communication channel between sensors, database and user is a prerequisite for this. The company must have a powerful cloud as a central location for storing and evaluating the maintenance data. It is recommended to implement a wireless Long Range Wide Area Network, which is adapted to the requirements of the Internet of Things.

Secure, bidirectional communication with end-to-end encryption can be realised via appropriate gateways. This type of management during the life cycle of machines and devices can lead to more sustainable production processes and corporate strategies. Necessary maintenance measures can be carried out precisely when action is actually required through the use of sensors.

In addition to higher machine availability through the avoidance of unscheduled downtime, this maintenance strategy scores with lower long-term costs and a lower expenditure of resources – compared to preventive and failure-oriented maintenance models.

Timly answers the question “What is maintenance?” – The app explained very simply in under 2 minutes

Simple and Intuitive Inventory Management With the Smart Timly App

(No credit card required)

What Is Maintenance Real Estate: Definition and Elements

There are also a number of administrative measures in the field of building maintenance as well as measures to maintain the functional condition. After all, in order to maintain the value and habitability of residential buildings, certain maintenance measures and their documentation are necessary. It is similar for commercial properties.

Many companies still manage their maintenance appointments and inspection documents on paper or in Excel lists. This approach is considered inefficient and risky: a spreadsheet is quickly lost or an employee overlooks a necessary entry.

To ensure the correct documentation of defective components or maintenance that has taken place, some companies install free maintenance management software. However, this software is not tailored to individual needs and often has too few functions. In the end, unnecessary opportunity costs are incurred if (construction) companies do not rely on a fee-based, specialised solution for the management of inventory and maintenance measures in good time. One of these specialised solutions to answer the question “what is maintenance” is the Timly inventory app.

What Is Maintenance Buildings: Elements and Strategies

An important part of building maintenance is the inspection, which is usually carried out by a building specialist or technician. This person records changes to the building or equipment photographically and in writing and looks for their causes. In addition to this assessment of the actual condition, other elements of maintenance are:

– the consideration of internal and external requirements,

– adherence to maintenance objectives, and

– the fulfilment of defined maintenance strategies.

In addition, certain improvements to buildings are currently relevant maintenance measures. Now and in the following years, building upgrades are often required in Germany and Europe by the Energy Saving Act or the Renewable Energies Heat Act.

All elements of building maintenance must be correctly documented. The creation and updating of corresponding database entries is more flexible with cloud-based software for maintenance than with (spreadsheet) software permanently installed on a PC. Because if damage, new appointments or maintenance notes can be entered directly on the mobile device in the building or company vehicle, this is less likely to be forgotten or postponed.

Example of Definition in Industry

What is maintenance in industry? In relation to a production plant, maintenance measures are understood to be everything that serves to monitor, maintain and restore the technical performance of the production plant required for the production purposes. Maintenance planning software, like Timly, must therefore be able to quickly indicate the current state of safety and functionality of the industrial plant. Optimally, it should provide an overview of which machines and plants are defective or profitable and how often.

In recent years, the trend has been away from preventive and towards condition-oriented maintenance measures. The reason for this was the advancing digitalisation. However, it is becoming more difficult to maintain an overview of this maintenance management without good software support. And documenting the functional condition of all equipment, inventory goods and vehicles is too relevant to rely on a flawed programme.

A test phase with free maintenance software can at best be useful for a young company with a small budget to get a feel for which functions are needed.

How to Implement: Industry, Trade, Construction and Other Sectors

Many companies continue to rely on classic maintenance strategies, while others are already using maintenance technologies such as smart sensors, data glasses or other visualisation solutions.

These are used to permanently determine and assess the condition of devices, systems, machines or vehicles.

What is maintenance – no longer a complicated question with Timly!

Regular maintenance and inspections, each carried out by a competent person, increase functionality and operational safety.

In order to record all maintenance data in the ongoing operation of a production plant or a fleet of vehicles and to share it with authorised employees, a high-quality, cloud-based software is recommended. Such a modern app for maintenance planning takes into account the fact that maintenance, inspection, improvement and repair are dynamic in many companies and are not clearly differentiated.

The proven inventory and maintenance software Timly is easily available and has already paid for itself for many companies. After all, good documentation saves all kinds of costs that were previously incurred due to forgotten inspection dates, duplicate maintenance, misplaced tools or non-communicated defects.

Similar Blog Articles:

Book an online demo - free and without obligation - or create your free trial account directly.