Maintenance: Definition, Sub-Areas and Optimisation Potentials

Maintenance: By Definition an Extensive Area

The ‘maintenance definition‘ covers a wide range of work, which aims to ensure that all devices and machines fulfill their required functions. It includes a wealth of technical and administrative measures that are important for occupational safety and a smooth production process. Malfunctions, defective components or declining device performance can lead to accidents, which is why correct maintenance is by definition also required by law. In order to comply with compliance regulations, more and more companies rely on maintenance software.

As a generic term, maintenance includes inspection, maintenance and repair. In addition, measures to improve operational processes and weak point analyzes are part of the maintenance area. Thus, maintenance includes the combination of all technical measures to maintain an optimal production process.

In retail as well as in industrial or construction companies (tool tracking software), maintenance software saves money and time in this regard. In addition, it indirectly ensures more security in the company, since it takes care of the management during the life cycle of all inventory goods. Maintenance by definition answers questions about the profitability of individual machines or systems. It includes inspection, i.e. the assessment of the actual condition of the equipment. Consequently, maintenance by definition documents how often which operating equipment is defective.

A Sub-Area of Maintenance: Upkeep

Unfortunately, some companies use inefficient methods to keep an eye on the necessary maintenance dates for all equipment. They let office staff create Excel lists or try out function-poor freeware. In many cases, this results in opportunity costs that could be avoided with professional inventory software. Such includes different areas of maintenance definition.

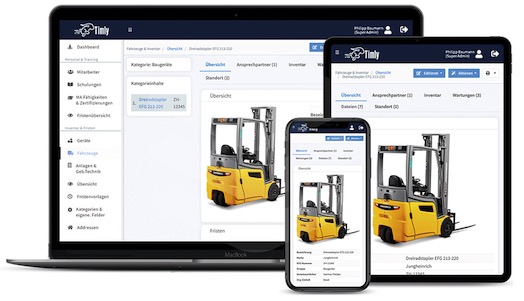

As a digital maintenance management software, Timly creates an overview of all tools, vehicles and systems, regardless of location. It manages test dates, loans and repair orders in a program that can also be used on the go.

Asset Management Software in Use by Our Customers

The Timly software is continuously evolving to meet the needs of our customers. In various success stories, we show you how Timly optimizes processes in companies, thereby saving significant effort. With Timly, inventory management becomes child’s play.

Optimized Device Management With Innovative Self-Inventory

SodaStream is the world market leader for water sparkling systems for domestic use and has a lot of IT equipment at its various locations. Many colleagues now work from their home offices. A digital solution for the efficient management of IT end devices became necessary...

Panasonic x Timly: Driving Technological Innovation

One of the most remarkable aspects of human ingenuity is our ability to innovate. Innovation is embedded in the DNA of consumer electronics giant Panasonic, which has diversified into a number of sectors, from heavy industry to construction...

Manage Video Equipment Efficiently Without Much Effort

The Hamburg media company always does outstanding journalistic work and is characterized by independent reporting. In order to maintain journalistic quality, the teams work with highly specialized devices – these need to be managed efficiently...

Smart City Asset Management – Timly in Use at DIGOOH

The core business of DIGOOH Media GmbH in Cologne is to manage digital city light posters (DCLP) for outdoor use in various cities in Germany. The challenge here lies in making the client’s communication message always available at the right time, in the right place...

(No credit card required)

Maintenance: Definition and Typical Work Steps

With maintenance, usually annual, the target condition of the respective unit is restored. The aim is to delay or even prevent wear and tear. In order to maintain the warranty claim and to keep the resale value high, all maintenance must be properly recorded.

To ensure that the maintenance plan is correctly adhered to, it is advisable to use a modern maintenance programme that can be easily operated by all authorised persons. This avoids safety risks or production downtimes due to incomplete maintenance intervals.

Upkeep: Definition and Procedure

During repairs, the software-integrated tracking of defects and deficiencies via an internal ticketing system pays off. This can also be connected to external service providers using a corresponding interface. This keeps the overview of the entire company inventory in the digital inventory management.

Software Helps to Keep Servicing Tasks in View

According to UK laws (PUWER requirements), companies are required to maintain work equipment in an efficient and safe state. Maintenance is the combination of technical and administrative measures as well as management measures that serve to maintain or restore the functional condition of an inventory object in the life cycle.

In order to manage the complex, interlocking processes in a structured manner according to the common maintenance definition, especially in larger companies, there is no way around professional inventory software in the long term. Although this causes short-term costs, it leads to a noticeable improvement in operational processes after just a few months.

Similar Blog Posts:

Book an online demo - free and without obligation - or create your free trial account directly.