How Warehouse Inventory Management Eliminates Risks and Boosts Performance

In this article:

- Why efficient warehouse inventory management is more critical than ever

- Warehouse inventory management: Understanding what’s at stake

- Exploring the digital evolution of warehouse management systems

- Inventory management vs warehouse systems: Clarifying the differences

- Optimising operations with ABC analysis

- Understanding the core functions of WMS

- Asset tracking tool: More stock accuracy and efficiency

- Timly’s asset tracking solution: A 360° alternative to traditional WMS

As customer demands change, warehouse inventory management is more critical than ever.

Why efficient warehouse inventory management is more critical than ever

Effective warehouse inventory management is crucial for a business to continue thriving in today’s competitive market. It ensures that operational efficiency is maintained, not least to meet customer demands. This article explores the intricacies of warehouse inventory systems, highlighting the importance of managing stock levels optimally to minimise waste and prevent overstocking or understocking. A robust warehouse inventory management system is fundamental in achieving these objectives. We will examine practical strategies and tools, including the benefits of a fully-fledged warehouse management system (WMS) compared to more versatile tools, like asset tracking tools for inventory management in your warehouse and beyond – with the ultimate goal to streamline operations, achieve efficiencies, and reduce costs.

Warehouse inventory management: Understanding what’s at stake

Effectively managing your inventory has implications that go beyond internal efficiencies: improper inventory management can lead to increased operational costs and, more critically, disruptions in deliveries to your customers. The stakes are high. The ripple effect of these disruptions can be profound, affecting customer trust and your brand reputation. Therefore, successful warehouse inventory management is not just a logistical necessity, it’s a strategic imperative that directly impacts your business’s bottom line and customer satisfaction.

In essence, the core of warehouse inventory management is to achieve a delicate balance. It’s about having enough stock to meet demand without overburdening your resources or budget. This balance is key to maintaining smooth operations and ensuring that your business stays agile and responsive in a dynamic market environment. For a comprehensive approach to tracking, maintaining, and optimizing all physical assets in your warehouse, discover our warehouse asset management solution.

Over 600 Companies, Schools and Cities Rely on Timly

Exploring the digital evolution of warehouse management systems

In a digital era, it is hard to think about warehouse management without a proper technical solution. Advanced WMS has revolutionised warehouse processes, enabling streamlined operations from inbound to outbound logistics. Modern warehouse management software, a key component of WMS, offers automation and efficiency in managing complex warehouse tasks. Integrating WMS with supply chain management modules increases visibility and coordination across the supply chain, enhancing overall efficiency. These systems can be broadly categorised into three types, each with unique features and benefits, as outlined below:

1. Standalone Warehouse Management Systems: Tailored for basic needs, these systems focus on core tasks such as inventory management, picking, packing, and auditing. Ideal for smaller operations or those with limited IT resources, standalone systems are cost-effective and relatively simple to implement, making them suitable for businesses beginning to automate their warehouse operations.

2. Supply Chain Modules: These WMS modules, part of a broader supply chain management suite, offer advanced functionalities compared to standalone systems. Integrated with other modules like transportation management and enterprise resource planning (ERP), they provide a holistic view of the supply chain. This type is best suited for businesses with complex logistics needs and a desire for comprehensive supply chain insights.

3. Cloud-Based Warehouse Management Systems: Representing the forefront of WMS technology, these cloud-hosted systems combine traditional functionalities with scalability, flexibility, and reduced initial costs. They are ideal for businesses with multiple warehouse locations or needing remote access, offering benefits like real-time data analysis and enhanced operational efficiency.

The choice of WMS depends on factors such as warehouse size, operational complexity, budget, and the need for integration with other business systems, with each type offering distinct strengths to match different operational needs. Moreover, as we will see in the course of this article, there are many situations where a 360° asset tracking solution is the best alternative to a traditional WMS.

Inventory management vs warehouse systems: Clarifying the differences

As mentioned above, efficient use of warehouse space is a crucial aspect of warehouse management and plays a significant role in overall operational effectiveness. Conversely, properly managing stock levels is an essential component of inventory management, crucial for ensuring product availability while preventing overstocking.

A key part of a warehouse inventory system is understanding the differences between inventory management and warehouse management. Inventory management is concerned with the ordering, storage, and utilisation of goods, with a focus on maintaining optimal stock levels. In contrast, warehouse management deals with the physical storage and distribution of goods, encompassing tasks like layout planning and stock location. Both are critical functions that are interconnected and that work together to achieve streamlined supply chain operations.

Timly’s software explained in under 2 minutes

Keep an Eye on Your Warehouse Inventory with the Timly Smart Asset Management Software

(No credit card required)

Optimising warehouse operations with ABC analysis

One of the most useful techniques in inventory management is ABC analysis, aimed at optimising stock levels to enhance operational efficiency. This method categorises inventory into three classes based on their importance, taking into account factors such as demand, cost, and risk to optimise resource allocation:

Class A items: These are high-demand, critical items that make up a significant portion of inventory value. They require meticulous management and regular monitoring due to their importance.

Class B items: These items have intermediate importance, being less critical than Class A but more significant than Class C items. They warrant moderate attention and management.

Class C items: These items, while abundant and less valuable, are essential for supporting the availability of Class A and B items. Hence, efficient management of Class C items is crucial for overall inventory balance.

Implementing ABC analysis in inventory management enables effective resource distribution. Class A items need stringent control and frequent reordering, while Class C items might be managed with larger safety stocks and less frequent oversight. This approach, focused specifically on inventory management and distinct from activity-based costing in cost accounting, ensures that essential items are always available, fostering cost-efficient and effective operations.

Understanding the core functions of WMS

The smooth operation of warehouses is heavily reliant on the integration of advanced technology and efficient management practices. Effective inventory control is key to maintaining real-time visibility and accuracy of stock levels. For instance, efficient order fulfilment is a critical function that directly impacts customer satisfaction and retention. WMS facilitate seamless picking, packing, and shipping processes, essential for timely deliveries. Understanding the fundamental functions of a WMS is crucial in elevating warehouse operations. These functions include:

> Inventory Tracking and Control

This feature allows for real-time monitoring of stock levels and movements, ensuring up-to-date inventory information.

> Order Fulfilment and Processing

This automates the entire order process, from receipt to dispatch, streamlining operations and reducing manual intervention.

> Labour Management and Optimisation

This focuses on improving labour distribution and productivity, ensuring that human resources are used efficiently.

Asset tracking tool: More stock accuracy and efficiency

Automating the tracking process significantly reduces the risk of human error, thereby enhancing overall inventory accuracy. Implementing an effective asset tracking tool is vital in modern warehouse inventory systems. With inventory being tracked through advanced tools, businesses can greatly reduce errors in stock counts. Tools like QR-enabled asset tracking provide a straightforward and efficient method for monitoring inventory, substantially improving data accuracy and operational efficiency. For businesses where a full WMS may not be necessary, QR-enabled asset tracking presents a simpler yet effective solution for efficient asset management. It offers a cost-effective alternative for smaller businesses or those with limited budgets, ensuring efficient warehouse operations.

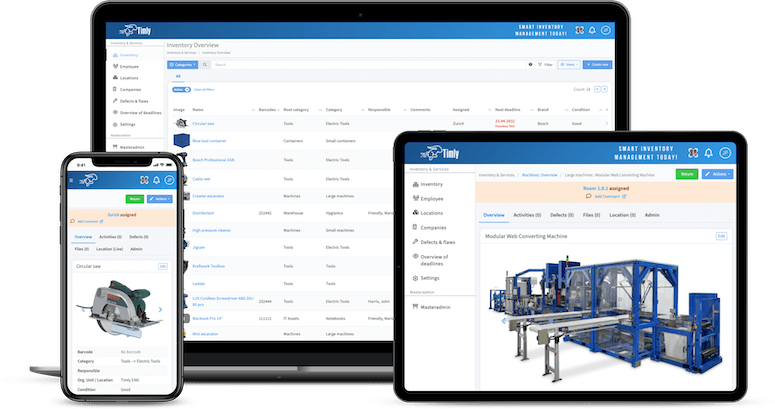

Timly’s asset tracking solution: A 360° alternative to traditional WMS

Choosing the right tools and strategies is crucial to ensuring efficiency in warehouse inventory management. Timly presents a dynamic alternative to traditional standalone WMS, offering a flexible and user-friendly solution for warehouse inventory management and asset tracking across your business. This is achievable thanks to the high level of customisation Timly offers and the technologies it employs, including cloud and QR technology. These technologies not only simplify the tracking and management of assets but also make it easily accessible from anywhere.

With Timly’s asset tracking solution you can keep an eye on inventory levels.

With Timly you have a versatile and easy-to-implement warehouse management solution that is fully adaptable to the evolving needs of your business. It serves as a very valid alternative to more complex warehouse management systems, enhancing not only warehouse inventory management but asset tracking and optimisation across your business as a whole.

Recommended for you:

Book an online demo - free and without obligation - or create your free trial account directly.