Timly in Kürze erklärt

Wir machen Inventarverwaltung einfach

Verlieren Sie nie wieder den Überblick über Ihr Inventar mit der intuitiven Inventarsoftware, die sich an Ihre Arbeitsweise anpasst.

Timly in Kürze erklärt

Über 500 Firmen, Schulen und Städte vertrauen auf Timly

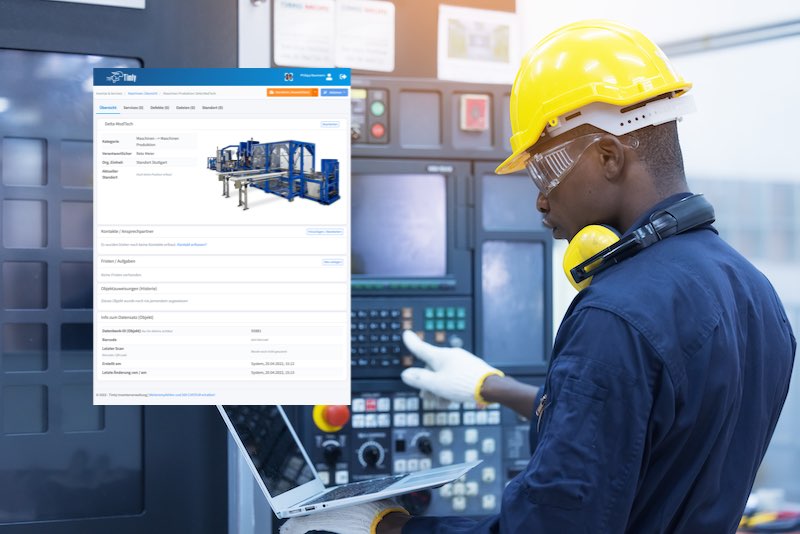

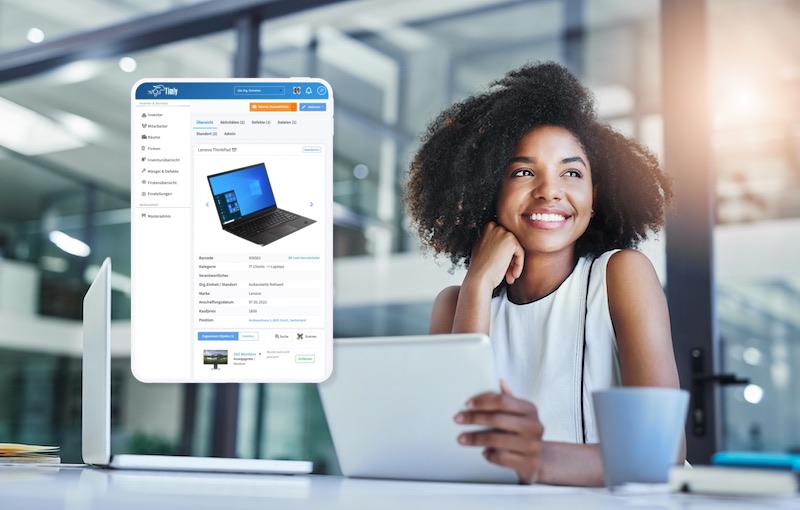

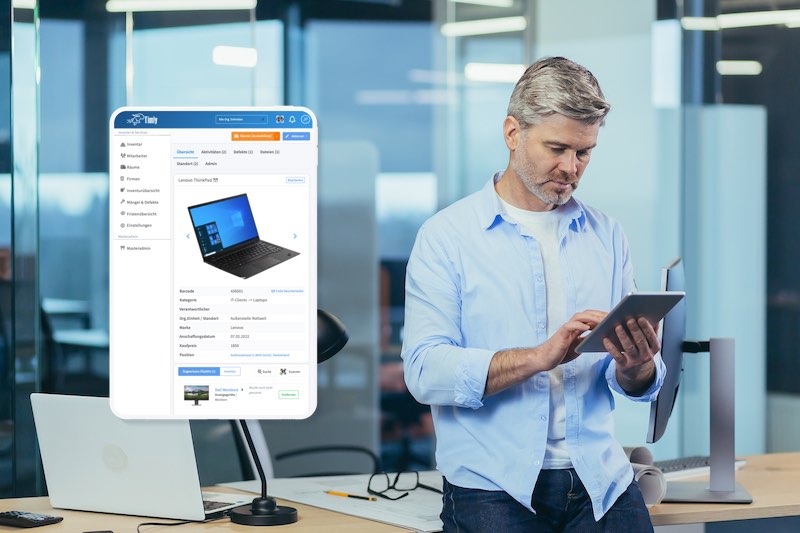

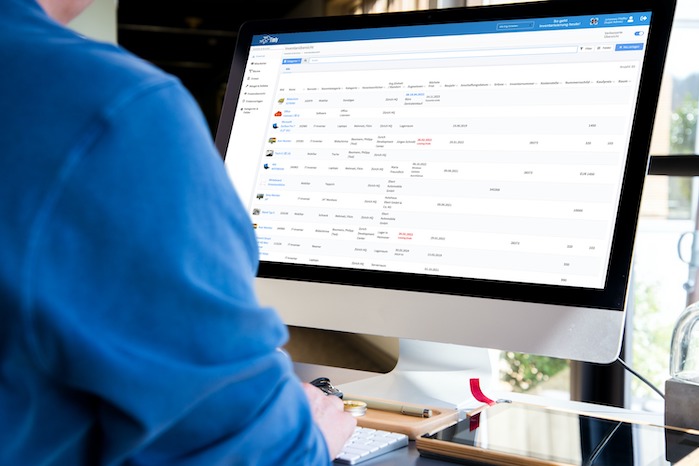

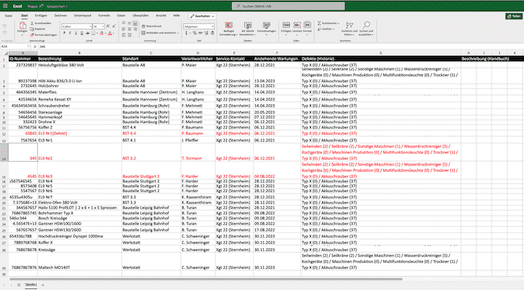

Intuitive Inventarverwaltung Software für moderne Unternehmen

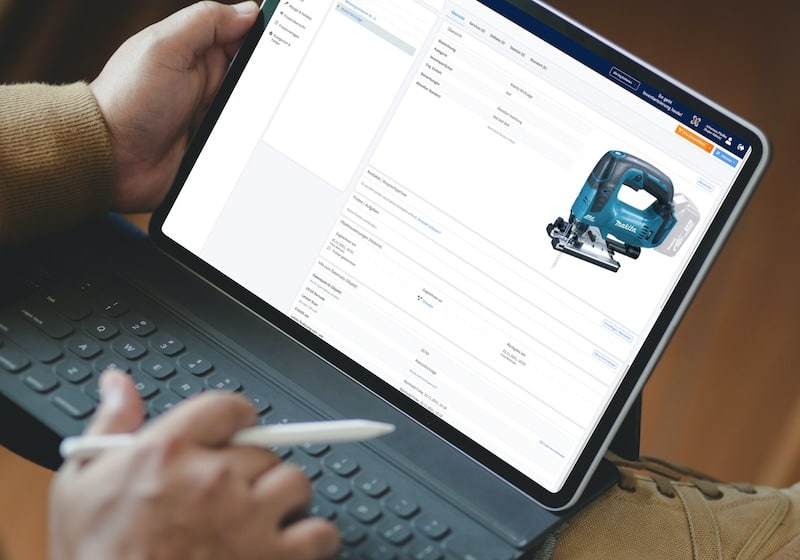

Mit Timly erhalten Sie Zugang zu einer effizienten Inventarverwaltung Software. Ein breites Spektrum an ausgeklügelten Funktionen ermöglicht Ihnen die einfache Digitalisierung Ihres Inventars.

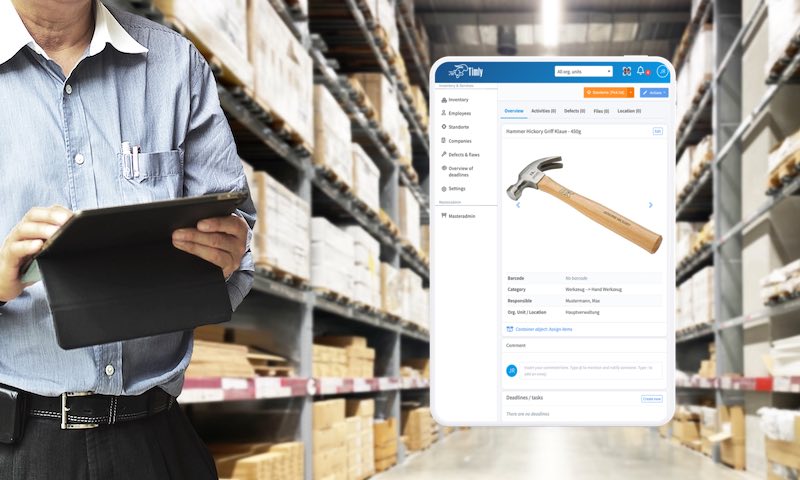

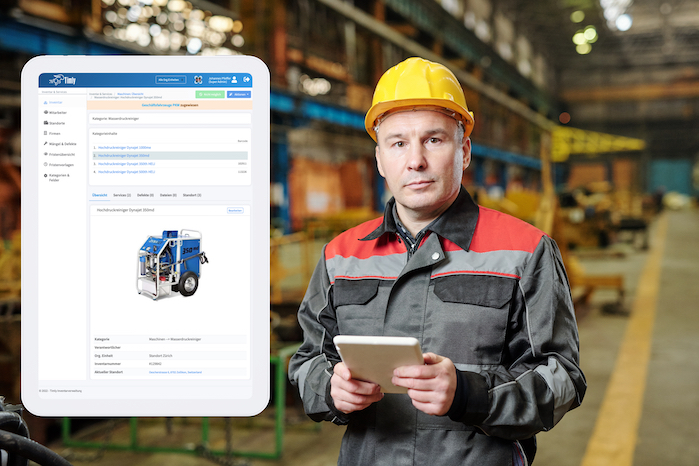

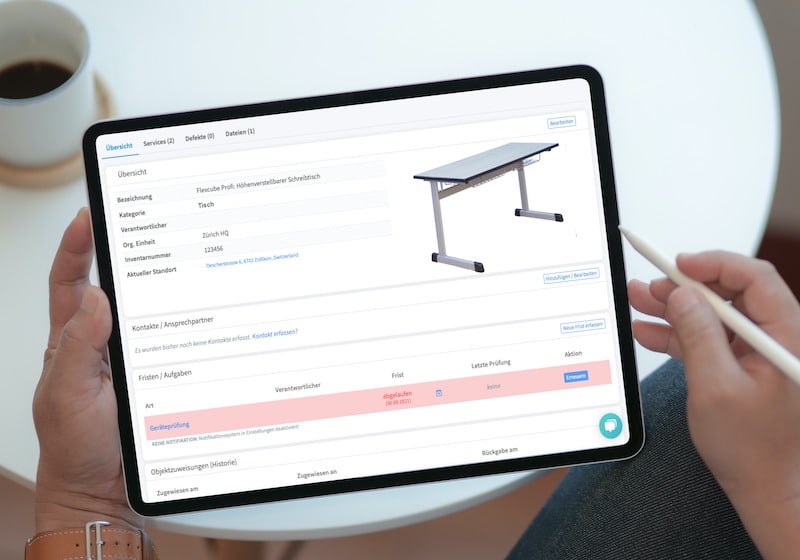

Alles inventarisieren

Egal ob IT-Assets, Möbel, Werkzeuge, Geräte oder Maschinen. Timly ist vollständig modular aufgebaut und erlaubt es Ihnen jegliche Art von Inventar zu verwalten, egal ob auf dem Desktop oder mobil von unterwegs.

Automatisiertes Wartungsmanagement

Durch die Automatisierung von Wartungsprozessen optimiert Timly Produktivität und Effizienz, was zu geringerer Ausfallzeit, verbesserter Anlagenzuverlässigkeit und gesteigerter betrieblicher Effektivität führt.

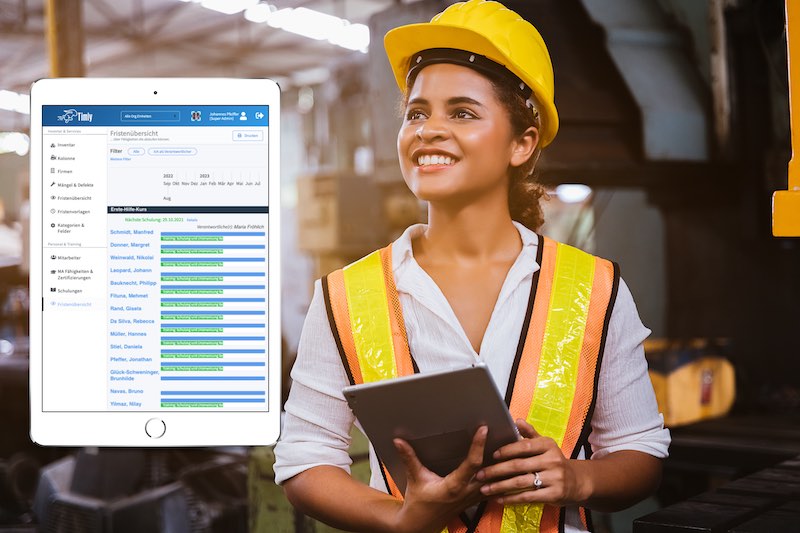

Mitarbeiterfähigkeiten verwalten

Wer darf die Geräte und Maschinen bedienen? Wann muss welcher Mitarbeiter seine Zertifizierungen erneuern? Timly ist die Verknüpfung Ihres Inventars mit den Mitarbeiter-Fähigkeiten und garantiert Compliance.

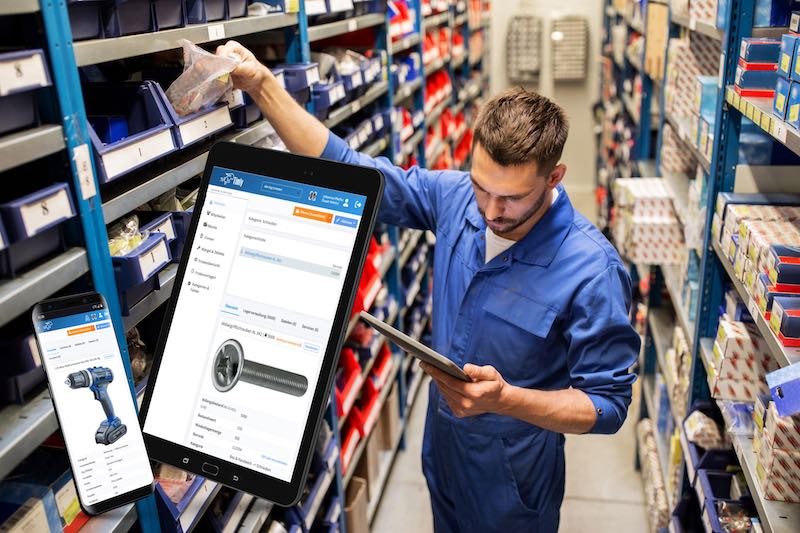

Verbrauchsartikel tracken

Kontrollieren und optimieren Sie den Konsum Ihrer Verbrauchsartikel wie zum Beispiel Sicherheitsausrüstung, Teile oder Büromaterial. Timly informiert Sie über Warenein- & ausgänge, sowie niedrige Füllstände.

Inventuraufwand minimieren

Durch die 360° Übersicht in Timly führen Sie Ihre jährliche Inventur zeitoptimiert durch. Innovative Funktionen ermöglichen ein vollständiges Bild über Ihr Unternehmensinventar – auch für Home-Office-Inventar.

GPS-Live-Tracking (IoT)

Durch IoT-Live-Tracker können Sie Daten wie Standort, Verbrauch, Füllstände und mehr in Echtzeit einsehen. Dadurch hilft Timly Ihnen dabei, die Kosten Ihrer schweren Anlagen und Maschinen zu optimieren.

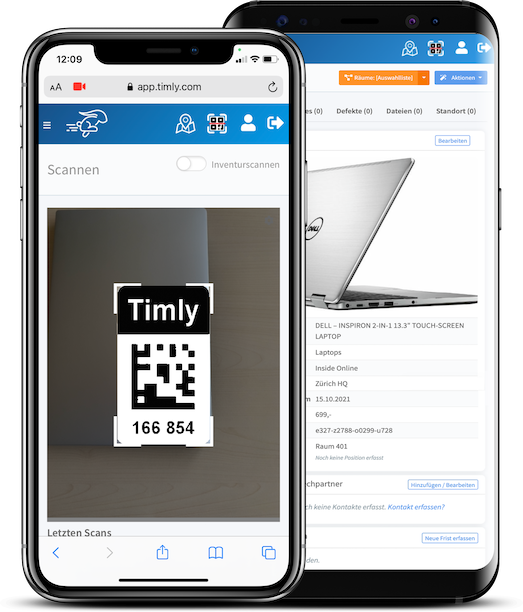

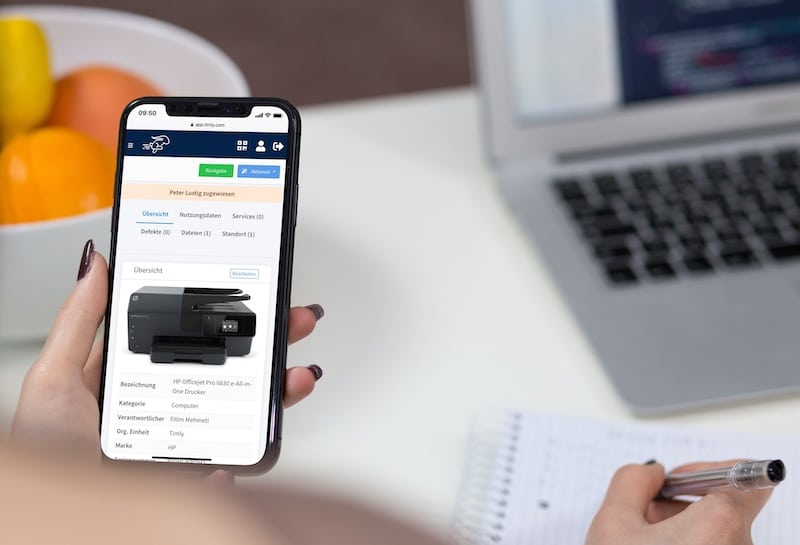

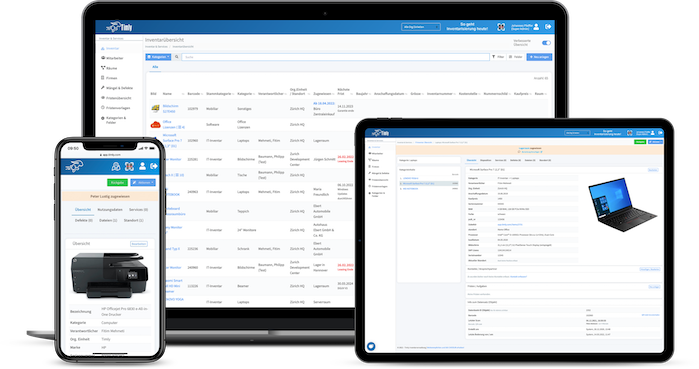

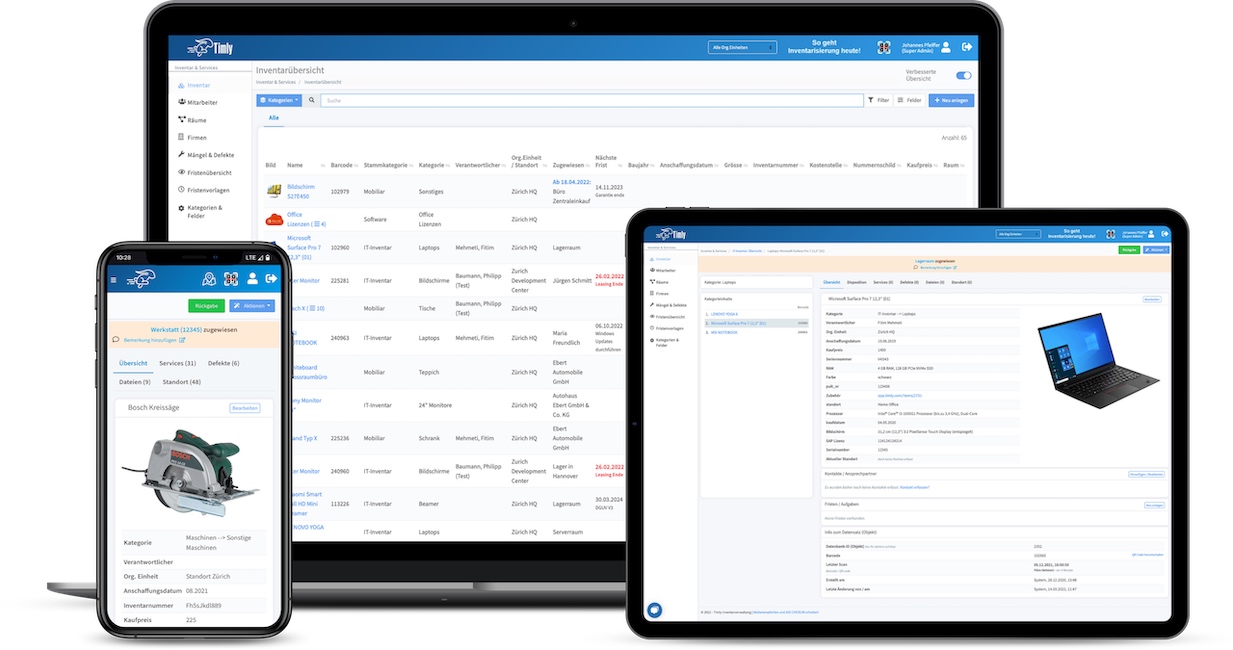

Auf jedem Endgerät nutzbar

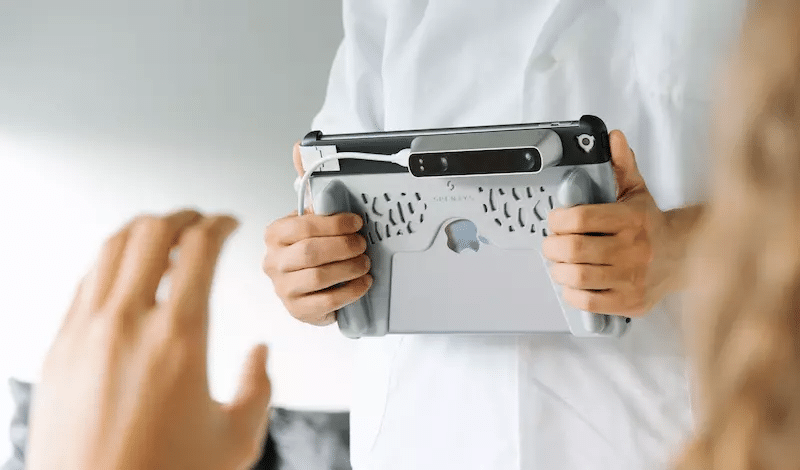

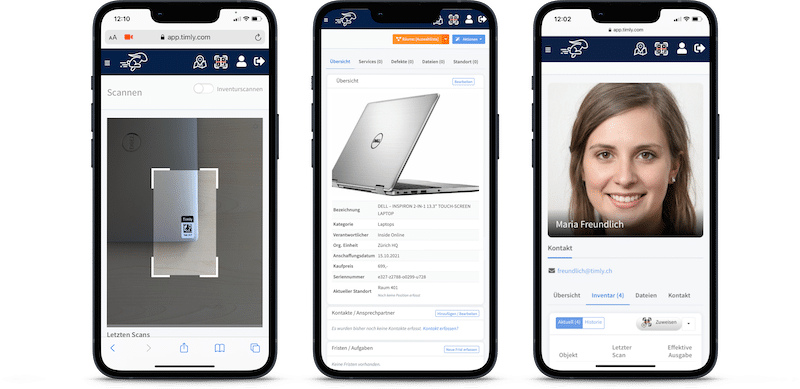

Die online Inventarverwaltung von Timly erlaubt Ihnen Zugriff auf Informationen überall dort, wo sich das Inventar befindet. Steuern Sie alle wichtigen Prozesse auch auf Ihren mobilen Geräten.

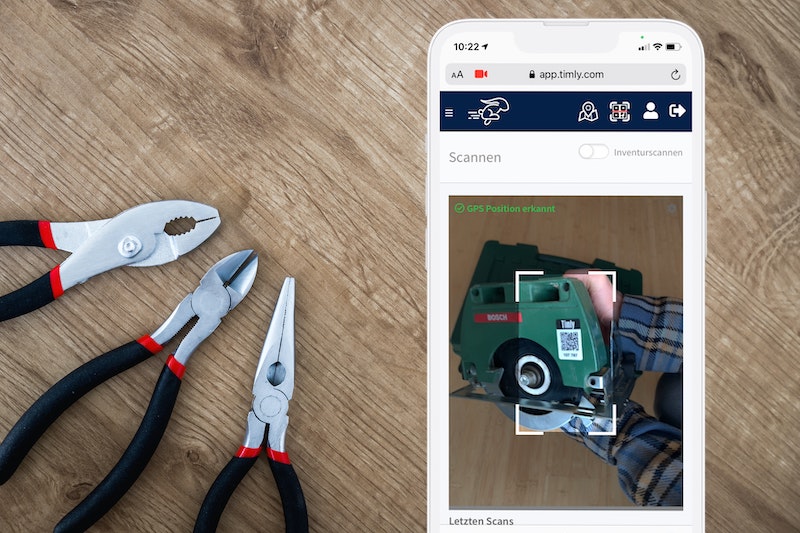

Integrierter Barcode-Scanner

Die Inventarverwaltung ist auf dem Tablet & Smartphone jederzeit vollumfänglich nutzbar – Sie brauchen keine zusätzliche Hardware.

Über den Barcode-Scanner können Sie mit einem einfachen Scan ganz einfach auf die Informationen zu Ihrem Inventar zugreifen, sowie Aktionen ausführen.

Aktionen mobil durchführen

- Alle Infos & Dateien vor Ort griffbereit

- Reparaturen & Services erfassen und dokumentieren

- Fristen Management & Wartungsplaner

- Inventar zuweisen (check-in | check-out)

- Defekte melden und tracken

Inventar Standorte & Inventur

Mit dem Smartphone oder Tablet können Sie bei jedem Scan eines Objektes den genauen GPS Standort erfassen lassen.

Für die Inventur ergibt sich durch die Massenerfassung via Barcode-Scanner ein erheblicher Zeitvorteil.

Einfache Integration in Ihre Unternehmensprozesse

Verwalten Sie mit unseren Integrationen alles zum Thema Inventar an einem Ort. Durch die Rest-API können wir uns mit praktisch jedem System verbinden, das in Ihrem Unternehmen läuft. Integrieren Sie Timly in Ihre Prozesse und synchronisieren Sie mit einem Klick nahtlos alle Daten, die Sie täglich brauchen.

75%

Weniger Geräteausfälle und Inventarverlust

90%

Zeitersparnis bei der Inventarverwaltung

500%

Return on Investment (ROI)

Digitalisieren Sie Ihre Inventarverwaltung noch heute!

Einfach. Schnell. Zuverlässig.

Warum die weltbesten Unternehmen Timly nutzen

Großes Lob an Sie und das Timly Team. Bei uns arbeiten alle wirklich sehr gerne mit Timly und wir werden Ihr Tool mit Sicherheit noch in anderen Bereichen einführen.

Unsere IT Inventarisierung klappt mit Timly jetzt völlig unproblematisch. Zuvor hatten wir uns auf die gängige Art und Weise verlassen, bei der man allerdings schnell mal den Überblick verliert. Die Digitalisierung der Prozesse mit der Timly Software bringt einen echten Mehrwert und minimiert den Verwaltungsaufwand.

Timly ist in unserem Unternehmen ein etabliertes System. Dank Timly haben wir immer ein umfassendes Bild von unserem Inventar. Genau so haben wir es uns vorgestellt.

Inventarverwaltung Software im Einsatz bei SodaStream – Die „Selbstinventur“

🧮📲 ✅ Die Timly-Software entwickelt sich kontinuierlich weiter, um den Bedürfnissen unserer Kunden gerecht zu werden.

In diesem Anwendungsfall zeigen wir Ihnen, wie Timly den Inventarisierungs- und Inventurprozess in Ihrem Unternehmen vereinfacht. Durch optimierte Abläufe sparen Sie zukünftig erheblichen Aufwand bei der Inventarverwaltung. Mit dieser innovativen Funktion wird die jährliche Inventur zum Kinderspiel.

„Jetzt sparen wir enorm viel Zeit, weil die Mitarbeiter im Homeoffice auch nur 2 Minuten brauchen, um Ihre Assets zu bestätigen.“

Murat Tulgar – IT Manager